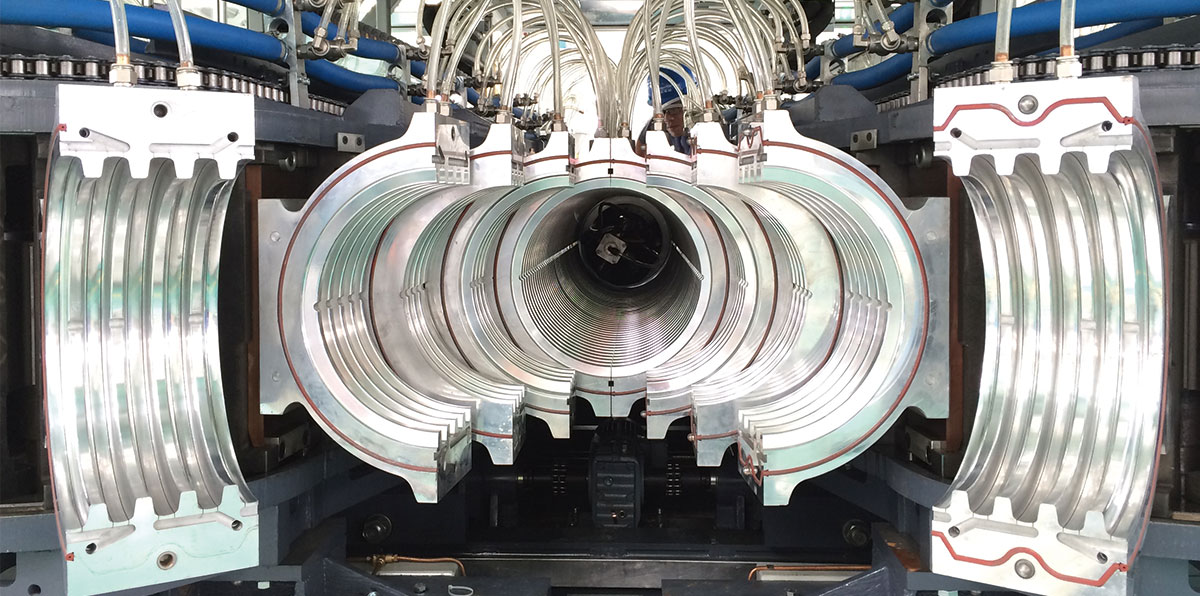

The mould blocks are made of special aluminum alloy for high stiffness and high thermal-conductivity.

Mould block are compatible between different corrugator models. Production will be more flexible.

Easy and quick mould block change by fasten/loosen one screw only, to further reduce your downtime.

Direct water cooling mould blocks, cooling water circulate with pressure in a closed circuit.

The vacuum channel and water passage are designed with very wide flowing cross-section in order to ensure producing stably with high efficiency.

The mould blocks are manufactured by pressure casting for imporosity and higher stiffness.

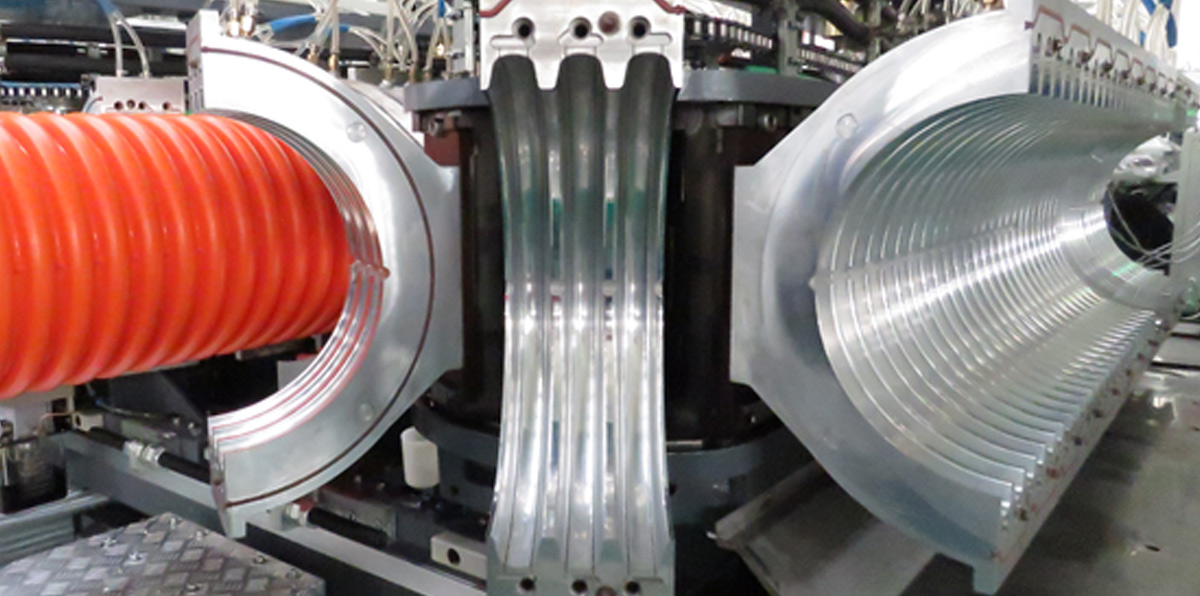

Independent die head for each diameter, die head and mandrel can be taken out from the line entirely as a whole when changeover. No need to dismantle the die head. It not only makes the changeover easier and faster to shorten the downtime, but also ensures the precision and long lifespan of the die head by less dismantling.

The new die head with spiral channel can lower flow resistance of material effectively and improve the plasticizing effect through greatly shortening the channel length.

The die head supporter is connected to corrugator base together as a whole, no need lateral adjustment for die head when changeover, it makes changeover much easier to shorten the downtime.

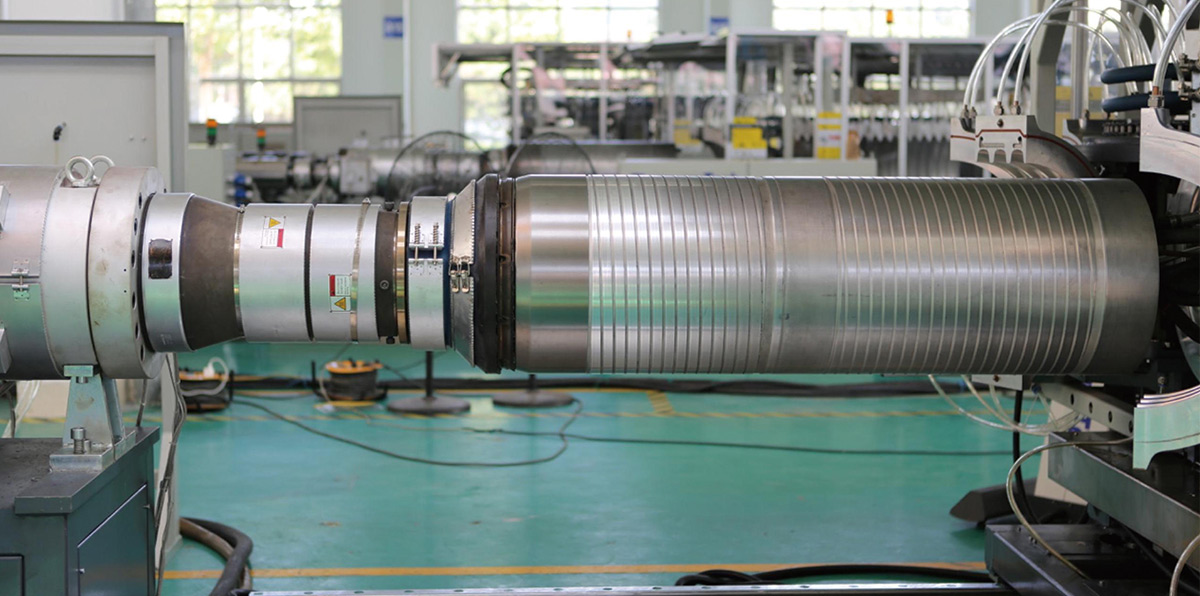

Innovated long calibrating mandrel, the length of mandrel is doubled for higher cooling efficiency.

Optimized multi-inlet cooling channels in the mandrel also contribute to the better cooling effective.

Vacuum suction for mandrels is available for each diameter to get better pipe quality.

Based on the continuous optimization of product quality and performance, the product pictures and parameters involved in this page may be different from the real products. Zhongyun reserves the right to modify the appearance design and configuration parameters of the equipment without prior notice.